SUTD developed a simple method to print planar microstructures of polysiloxane

SUTD - Rahul Karyappa, Terry Ching and Michinao Hashimoto

The new method, embedded ink writing (EIW), enables direct writing of polysiloxane which helps in the fabrication of microfluidic devices, flexible wearables, and soft actuators.

Polysiloxane is an elastic polymer which is widely used in fluidics, optics, and biomedical engineering. It offers desirable properties for microfabrication due to its castable and curable properties.

To produce small scale structures consisting of polysiloxane, soft lithography is used as a standard technique in academic research laboratories.

Recent advances in digital fabrication, in particular 3D printing, have enabled direct patterning of polysiloxane albeit with strict requirements for the properties of the printing inks. Suitable inks are usually highly viscous and fast-curing. For 3D printing, the yield stress or photocurable characteristics of the polysiloxane resins are required to allow them to retain the printed shape.

The low viscosity of the additive-curing polysiloxane makes them incompatible for printing with direct ink writing (DIW) 3D printers. While the low viscosity of the polysiloxane resin such as Sylgard 184 facilitates easy extrusion through the nozzles, the reflow of the patterned resin can compromise the print fidelity.

Researchers from Singapore University of Technology and Design’s (SUTD) Soft Fluidics Lab developed a simple method to fabricate reproducible planar microstructures consisting of polysiloxane using commercially available liquid polysiloxane resins without changing their properties.

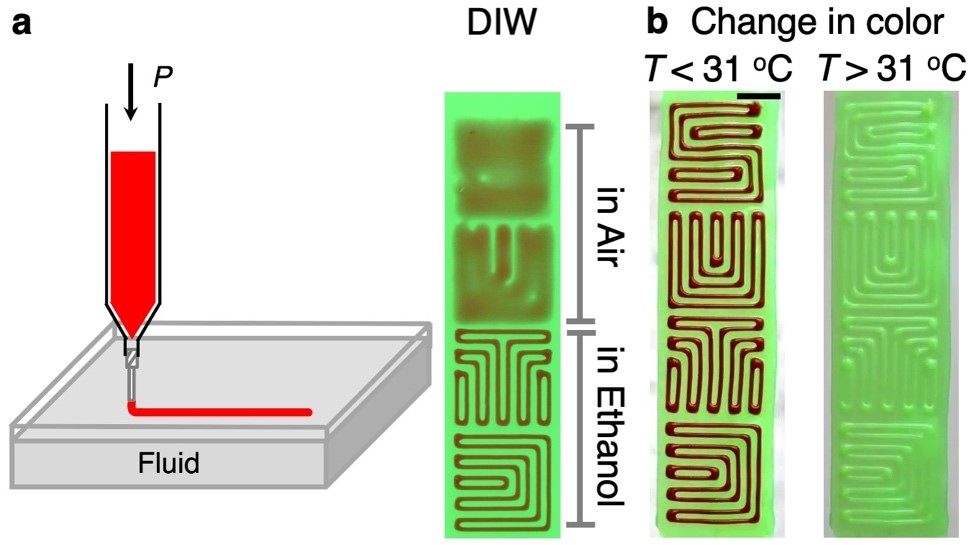

In this newly developed approach, curable liquid polysiloxane with the viscosity in the range of 1–100 Pa.s was dispensed in a liquid immiscible with the resins such as methanol, ethanol, and isopropanol. The contact angle of the dispensed polysiloxane on the substrate increased from 20o in the air to 100o in alcohols. The increase in the contact angles allowed maintaining the structures of patterned polysiloxane until curing, after which the embedding liquid was readily removed by evaporation. The method was termed as embedded ink writing (EIW) (refer to image).

Concept of embedded ink writing (EIW). A polysiloxane ink is printed by a direct ink writing (DIW) 3D printer in Newtonian fluids as embedding media. The surrounding liquid media allow the inks to maintain larger contact angles (> 100o) on the substrates. Inks for EIW can be functionalized by suspending functional microparticles (e.g., embedding thermochromic leuco dye microparticles).

Concept of embedded ink writing (EIW). A polysiloxane ink is printed by a direct ink writing (DIW) 3D printer in Newtonian fluids as embedding media. The surrounding liquid media allow the inks to maintain larger contact angles (> 100o) on the substrates. Inks for EIW can be functionalized by suspending functional microparticles (e.g., embedding thermochromic leuco dye microparticles).

“With EIW, polysiloxane inks can be patterned on different soft and rigid substrates without compromising the adhesion of the printed polysiloxane with the substrate,” explained lead author Dr Rahul Karyappa from SUTD.

“The presence of embedding media did not hamper the bonding of the polysiloxane filaments in both lateral and vertical arrangements, allowing this technology to be effective especially in fabricating flexible devices and microfluidic devices using commercially available PDMS resin,” added principal investigator, Assistant Professor Michinao Hashimoto from SUTD.

The research work was published in ACS Applied Materials and Interfaces, a leading journal that encourages newly-discovered materials and interfacial processes. Terry Ching, a PhD scholar at SUTD, also participated in this research project.

Reference: Embedded Ink Writing (EIW) of Polysiloxane Inks, ACS Applied Materials and Interfaces, DOI: 10.1021/acsami.0c03011

Acknowledgements

R.K. and M.H. thank Digital Manufacturing and Design Center (DManD Center) at Singapore University of Technology and Design for the project support (RGDM1620503) and the Agency for Science, Technology and Research (A*STAR) (A1983c0039). R.K. thanks Prof. Rochish Thaokar (Department of Chemical Engineering, Indian Institute of Technology Bombay, India) for useful discussions on the Rayleigh−Plateau instability.